Oxford Technical Solutions (OxTS) has launched precision time protocol (PTP) master functionality on all of its next-generation inertial navigation systems (INS). This option particularly benefits surveyors conducting UAV operations and automotive engineers managing test campaigns. The shorter time-to-survey enhances the user experience, and the higher quality final output means that many users will demand their sensors are PTP-compatible before considering them for their projects.

PTP synchronizes all clocks throughout a computer network. It is used in many industries to synchronize financial transactions, mobile phone tower transmissions and sub-sea acoustic arrays. Now this precise timing capability is also available to applications employing inertial navigation solutions.

Time Synchronization

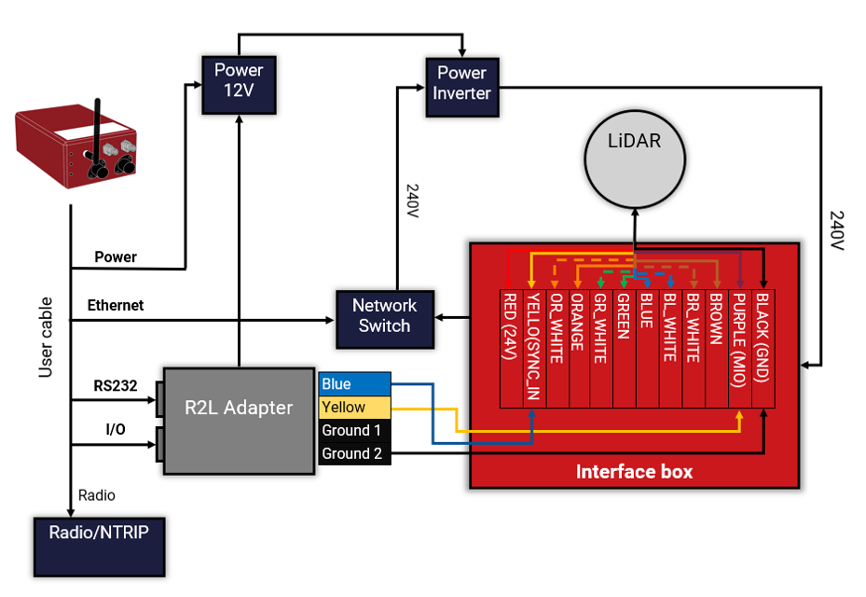

In many commercial organisations, millisecond-level device synchronization, as offered with Network Time Protocol (NTP), is sufficient. However, in surveying and automotive testing environments where there is more than one clock source (LiDAR and INS for example), final results can suffer from time drift if millisecond — rather than microsecond – synchronisation is used.

Time drift becomes relevant as soon more than one data acquisition system working in parallel in introduced. Each system contributes its own timing error, and over time this error will grow and create drift.

For surveyors, time drift can negatively impact pointclouds by making object recognition difficult, leading to blurring and double vision.

For automotive engineers running test campaigns, analysis of events within the data may be misaligned, making the analysis more difficult and/or less efficient.

Stamping Out Time Drift

To stamp out time drift it is important to use the most accurate clock-source available.

A key component of an INS is the GNSS receiver. The GNSS receiver acquires data, including timing information, directly from multiple GNSS constellations (GPS, GLONASS, BeiDou and Galileo). The GNSS receiver, coupled with the inertial measurement unit within the INS, allows users to benefit from the centimeter-level position accuracy that is so important in surveying and automotive testing environments.

GNSS satellites carry the most accurate time source possible: atomic clocks. This means that devices connected to a network that includes an INS can take advantage of this time source owing to the GNSS receiver within the INS.

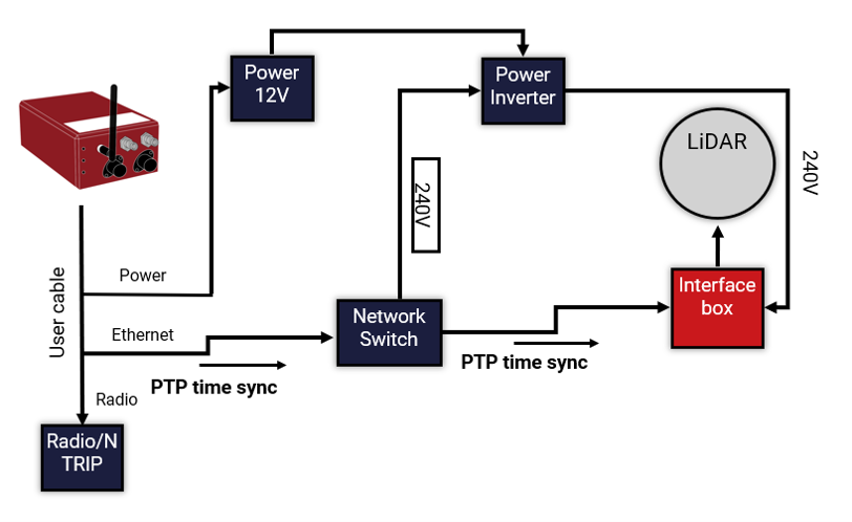

Simpler Set-up for LiDAR Use

By migrating from a traditional pulse per second (PPS) hardware set-up that involves connecting and wiring multiple cables to a PTP set-up, which is essentially an ethernet plug-and-play solution, users can also make day-to-day use of the equipment simpler and more efficient.

This much improved hardware set-up allows surveyors and automotive test engineers to be up and running in a much shorter timeframe than previously possible.

Adding Value to the Automotive Industry

The addition of PTP also adds value for automotive users. With cars-under-test incorporating multiple sensors (LiDARs, cameras etc), synchronizing all that data can help support accurate analysis after the test is complete.

OxTS is continuing to develop its PTP solution by working on PTP slave functionality and improving the configuration process, which will provide greater flexibility in typical automotive set-ups that use data acquisition units (DAQs) for larger sensor networks.

PTP as a time synchronization method is becoming more popular, particularly in the LiDAR industry, with manufacturers such as Ouster and Hesai enabling PTP on their sensors.

The shorter time to survey gives customers a much-enhanced user experience and the higher quality final output on offer means that many users will demand their sensors are PTP-compatible before considering them for their projects. Building PTP into complimentary sensors such as INS sets them up for success in the future.

Several OxTS INS are available to use PTP, including the company’s new xNAV650, a new small, lightweight and affordable INS for applications where payload size and weight matter.