GPS keeps a digital twin sequestered in El Segundo, California. Galileo has an Earth-bound space vehicle in Noordwijk, the Netherlands, straining at its bonds, yearning to break free and fly with its brethren. Both constellation “ghosts” exist in an eerie testing twilight, being made to replicate the movements and reactions of their free-flying families. Their sacrifices could lead to better, more robust satellites in future generations.

Constellation Clone

The U.S. Air Force Space and Missile Systems Center commissioned a digital replica of a GPS satellite, according to Air Force Magazine, to test the constellation’s cyber vulnerabilities. High-tech consultant firm Booz Allen Hamilton built the SatSim twin in 2018, based on Lockheed Martin’s Block IIR generation. They then tried to hack its various subsystems. This led to a chain of vulnerability scans and penetration tests of the satellite itself, ground control stations, and the radio-frequency links between them. Attacks on the communication links sought potential weaknesses between the satellite and its ground control station.

Neither the firm nor the Air Force will release test results. Any uncovered vulnerabilities remain cloaked.

Were a weakness to be found, “They can fix it in future satellites [or] they might be able to come up with workarounds or detection methods in current satellites,” according to BAH vice president Kevin Coggins.

The Air Force says it has previously employed digital twin methodology on other projects as well. The concept builds constructs with model-based systems engineering, focused on creating and exploiting domain models (software models that incorporate both behavior and data) as the primary means of information exchange. The practice has come into increasing use thanks to Moore’s law: the exponential improvement in computer processing speed. The virtual systems have the virtue of running much faster than real time. Engineers can simulate a year’s worth of full-bore functions in a few hours.

Galileo Double

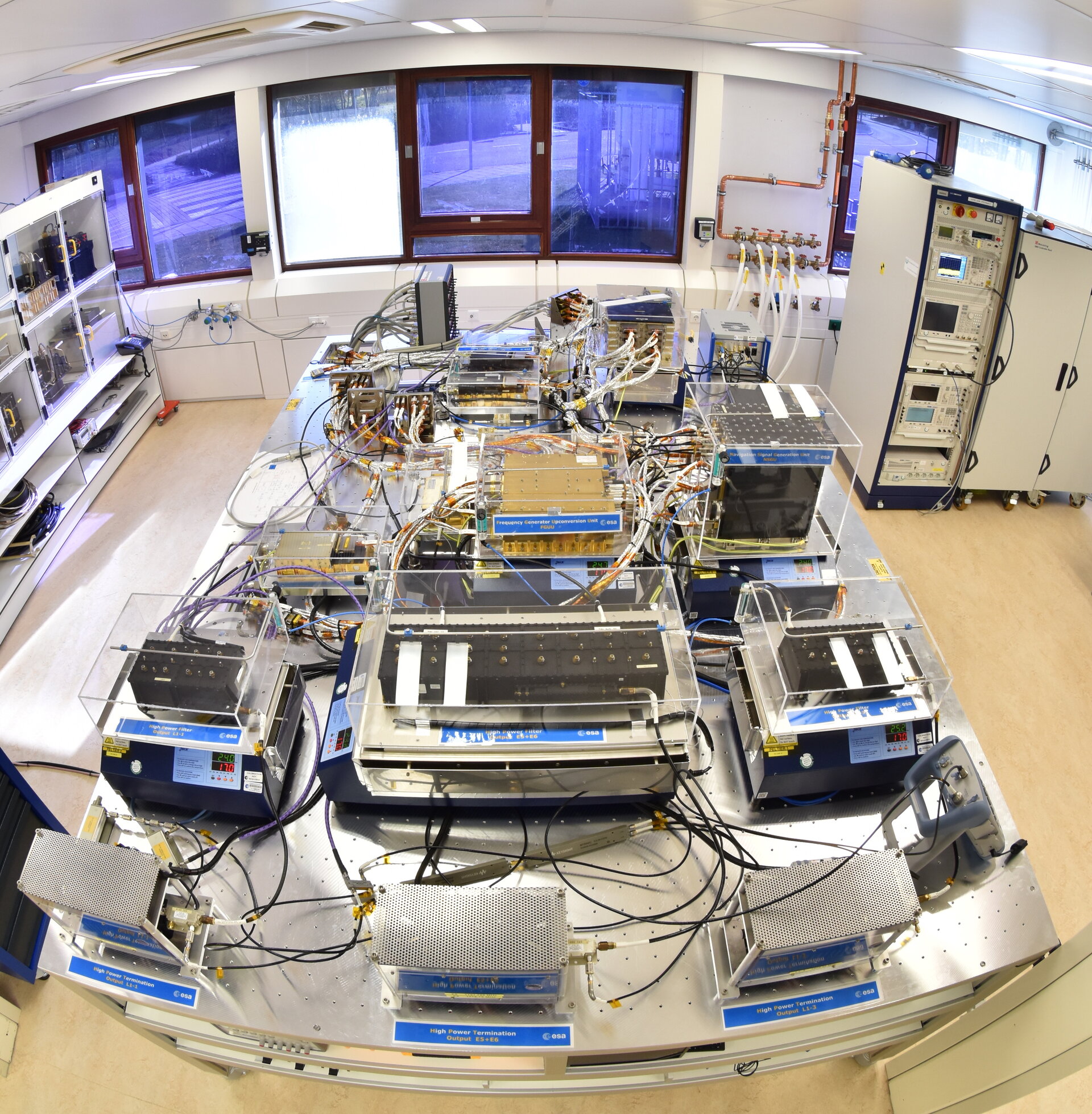

A complete Galileo satellite lives and breathes in a cleanroom within the European Space Agency’s ESTEC Microwave Lab. Built in 2016 by Thales Alenia Space in Italy at the time of the first-generation Galileo In-Orbit Validation satellites, this one never got to the launchpad. Instead, it was disassembled and its navigation payload put back together on a test bench. Engineers have since subjected it to many lab experiences, investigating the lifetime performance of its component parts, recreating satellite anomalies, and testing candidate technologies for Galileo’s future evolution.

The satellite’s key navigation system modules, the atomic clocks, solid state power amplifer, navigation signal generation unit (NSGU), frequency generator and upconverter unit were stitched back together with new cabling on a flat table. Instead of a satellite antenna, the motionless vehicle’s signals run through a dedicated attenuation chain to modify them as if they are being picked up by receivers on the ground.

ESA technician Gearóid Loughnane commented, “The payload and harness were designed for a cubic structure, rather than a flat table, so this was far from easy. In parallel we worked with the original vendors of the units, which at this stage were more than 15 years old, to source the operating software we’d need to get them working again.”

Surrey Satellite Technology Limited in the UK, Dutch aerospace company Terma, responsible for Galileo software, and ground control-equipment supplier Rovsing from Denmark all collaborated on the effort with ESA.

In 2019 the disembodied satellite underwent full radio frequency characterization testing, confirming the navigation payload performs as expected, as if in orbit, broadcasting the full range of current Galileo navigation signals E1, E5 and E6. Its next challenge will be testing technologies for the coming Galileo Second Generation design, set to fly later this decade, including plugging in a novel NSGU and new ensemble of atomic clocks.

To make it more representative of the Galileo Full Operational Capability satellites that form the majority of the current constellation in orbit, a second NSGU from Thales Alenia Space in Italy was added to the initial version made by RUAG, a Swiss company specializing in aerospace engineering.

The table-bound twin can generate the three Galileo navigation signals and reproduce a fully representative range of telemetry. Further, all its components can be separately temperature controlled, down to a single degree.

“This is important because part of the facility’s job is to recreate anomalies occurring aboard the satellites, which includes reproducing their environment,” said microwave engineer César Miquel España.

“The facility also allows the investigation and evaluation of end-to-end navigation signal performance of new satnav payload and equipment concepts.”