Kodiak Robotics, Inc. has been on a bit of a roll lately, developing automated solutions for long-haul truck routes in the southern parts of the U.S.

The self-driving trucking company made a big announcement on that front in August, unveiling a partnership with Pilot Company, the largest travel center operator in North America, to develop autonomous truck services at Pilot and Flying J travel centers.

The companies are creating an autonomous truck port in the Atlanta area to evaluate potential service offerings and explore scalable solutions. The possibilities include spaces to pick up and drop off autonomous trucking loads; conducting inspections; maintaining and refueling trucks; and the ability to transfer data for feature development and mapping.

The partnership is significant for both Kodiak and the industry. It establishes players like Pilot and its travel centers as premier locations to facilitate the various services autonomous trucks will need when they’re in production and deployed commercially, Kodiak CEO Don Burnette said. In addition, the Pilot centers will be access points for transferring data.

The Pilot partnership is just the latest development in Kodiak’s accelerating growth phase in 2022, with significant expansion coming in its service footprint and partner network as well.

In July, the company announced a partnership with 10 Roads Express, a provider of time sensitive surface transportation for the U.S. Postal Service, expanding the company’s service to Florida. And earlier this year, Kodiak announced a new route between Dallas and Oklahoma City with CEVA Logistics and a route between Dallas and Atlanta with U.S. Xpress.

A Fourth-Generation Autonomous Truck

This commercial success is being driven in part by the leading-edge technology in Kodiak’s fourth-generation autonomous truck. The new generation is designed for improved autonomous system robustness, with greater fleet uptime, manufacturing and serviceability in mind—all of which are critical to scaling the technology quickly, safely and efficiently, according to the company.

“Complex and bulky systems that require an engineer to hand-build and hand-tune are expensive, unreliable and difficult to debug,” said Burnette, who co-founded the Mountain View, CA-based Kodiak Robotics with Paz Eshel. “We believe that reliability and scalability flow from simplicity, and the best hardware modifications should be barely visible. Our fourth-generation platform is designed for simple, scaled production, which means easy calibration, troubleshooting and maintenance for our partners.”

The truck features a modular and more discreet sensor suite in three locations—a slim-profile “center pod” on the front roof above the windshield and pods integrated into both sideview mirrors. This better-integrated sensor placement is said to vastly simplify sensor installation and maintenance while also increasing safety.

The autonomous driving system features Luminar’s Iris LiDAR, Hesai’s 360-degree scanning LiDARs for side- and rear-view detection, ZF’s Full Range Radar, and the Nvidia Drive platform for the AI brains.

The Kodiak Vision perception system considers every sensor—including LiDAR, camera and radar—as primary, according to the company. All three sensors are purpose-built to meet the needs of autonomous trucks, which must “see” long-range in a variety of weather conditions to safely operate at highway speeds.

The system fuses information from the sensors and considers the relative strengths and weaknesses of each type. It incorporates extra redundancies and cross-validates data, adding another layer of safety to the self-driving system.

The patent-pending mirror pods—which will start with one Hesai LiDAR, two long-range 4D radars and three cameras—don’t require specialized sensor calibration. Rather than replacing a sensor in need of maintenance, a mechanic can replace the mirror pod in minutes. This single point of integration will allow for maintenance and serviceability at scale.

To make sense of all the data, the trucks will feature Nvidia Drive Orin, once available, as the supercomputing platform. With more than 250 TOPS (trillion operations per second) of compute performance, the platform is architected for safety and addresses systematic safety standards such as ISO 26262 ASIL-D (Automotive Safety Integrity Level-D). In the interim, Kodiak will use the current-generation Nvidia Drive AGX Pegasus to process data from cameras.

The Importance of PNT

When it comes to positioning, navigation and timing (PNT), Burnette said it “is definitely an area where we feel like Kodiak is really innovating within the space.”

Within a mapping and localization framework, he said “ultimately the robot needs to answer the question, ‘Where am I?’ And once it knows where it is, then it needs to ask the question, ‘How do I drive from here?’ And then you just repeat those questions.”

Historically, most companies have implemented high-definition (HD) maps of the environment using vehicle sensors to identify fine details like road texture surfaces, paint markings, tree trunks, buildings, sides of buildings, etc, Burnette said.

“You name it, they put it in the map, and then they use that map to position themselves very finely in the real world,” he said. “And then they use an IMU [inertial measurement unit] to interpolate between those position-based preferences.”

His company diverges from the industry in this respect.

“We do it differently,” he said. “We have a very sparse mapping solution that only includes the road network—the lane connectivity information.”

For instance, the Kodiak system and lightweight Sparse map keep track of the number of lanes and their relation to each other and know where the exits and

cloverleafs are.

“From there, we localize based on what our sensors see relative to the lane markings that are relevant for driving, much the same way [that] humans do,” he said.

Kodiak engineers use an IMU to interpolate truck location as it moves down the road.

“Our positioning is very high fidelity in a lateral sense, but it’s not as high fidelity in a longitudinal sense,” Burnette said. “It just doesn’t matter if we’re one foot farther or one foot back on the road. As long as we’re close enough to be within the vicinity, we can identify key markers to tell us where we need to take our exits and where to expect other vehicles to be.”

That’s where GPS comes in.

“We have a very loose reliance on GPS just to bootstrap the system when we’re just getting started to kind of tell us where we are initially,” he said, “but also then to pull us gradually along longitudinally to maintain that semi accuracy.”

Reliability is King

While performance and cost are important considerations for IMUs and GPS units—as well as the perception sensors—for autonomy, the key metric Kodiak developers are interested in is reliability.

“I think this is a bit of a surprise for most people, and it applies to all the sensors,” Burnette said. “At this stage, we’re not looking for improved performance. I think we have the performance we need from our sensors, compute and hardware that would be acceptable to launch this product safely. Cost is somewhat important, but what we really care about is reliability.”

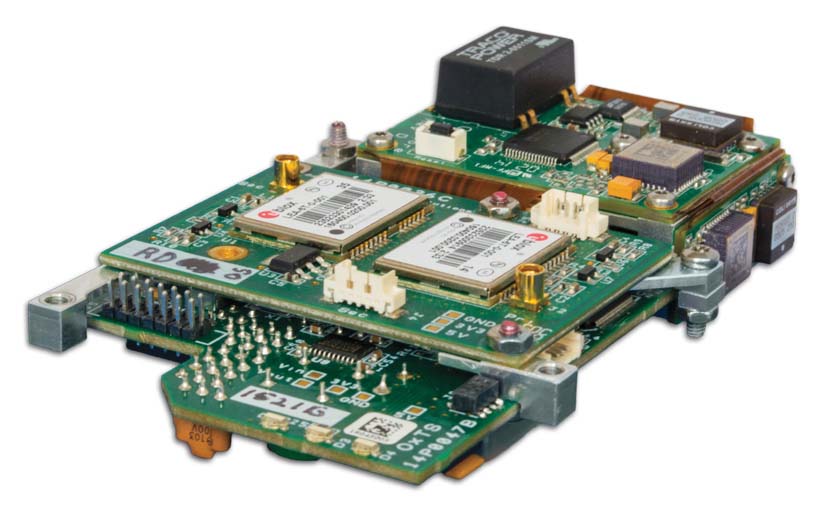

The company has not announced the sources for its IMU and GPS unit, but wants suppliers capable of building solutions that can withstand the harsh environment trucks face day in and day out without breaking.

“If you can build a unit that will go hundreds of thousands of miles on the highway without breaking, that’s what we care about,” he said. “We care about reliability much more than any kind of fancy gizmo.”

The ability to withstand the typical shock/vibration is a top consideration, especially for IMUs, along with water ingress and temperature swings.

“We drive in the heat of a Texas summer where it can get extremely hot, and it also must be able to work in the bitter cold,” he said. “So, temperature, shock and vibe, water, ingress, reliability—just general wear and tear—those are the types of things that we evaluate.”

Those evaluations continue as the company aims to integrate its self-driving software and hardware, the Kodiak Driver, into production customer trucks in early 2025. Kodiak Driver will operate self-driving fleets for a low per-mile subscription fee.