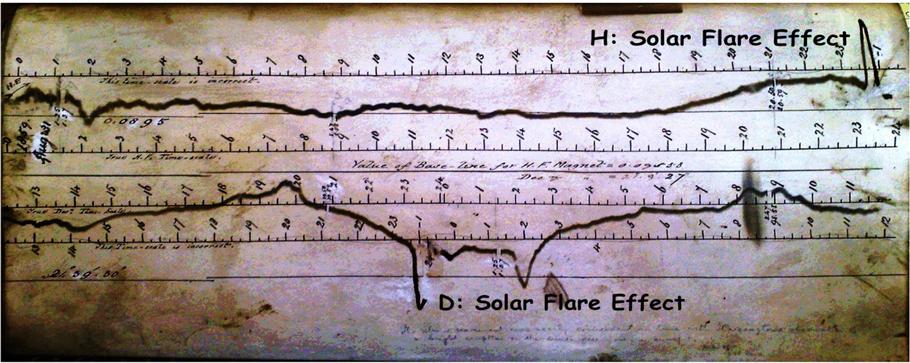

One of 12 magnetograms recorded at Greenwich Observatory during the Great Geomagnetic Storm of 1859

One of 12 magnetograms recorded at Greenwich Observatory during the Great Geomagnetic Storm of 1859 1996 soccer game in the Midwest, (Rick Dikeman image)

1996 soccer game in the Midwest, (Rick Dikeman image)

Nouméa ground station after the flood

Nouméa ground station after the flood A pencil and a coffee cup show the size of NASA’s teeny tiny PhoneSat

A pencil and a coffee cup show the size of NASA’s teeny tiny PhoneSat Bonus Hotspot: Naro Tartaruga AUV

Bonus Hotspot: Naro Tartaruga AUV

Pacific lamprey spawning (photo by Jeremy Monroe, Fresh Waters Illustrated)

Pacific lamprey spawning (photo by Jeremy Monroe, Fresh Waters Illustrated) “Return of the Bucentaurn to the Molo on Ascension Day”, by (Giovanni Antonio Canal) Canaletto

“Return of the Bucentaurn to the Molo on Ascension Day”, by (Giovanni Antonio Canal) Canaletto The U.S. Naval Observatory Alternate Master Clock at 2nd Space Operations Squadron, Schriever AFB in Colorado. This photo was taken in January, 2006 during the addition of a leap second. The USNO master clocks control GPS timing. They are accurate to within one second every 20 million years (Satellites are so picky! Humans, on the other hand, just want to know if we’re too late for lunch) USAF photo by A1C Jason Ridder.

The U.S. Naval Observatory Alternate Master Clock at 2nd Space Operations Squadron, Schriever AFB in Colorado. This photo was taken in January, 2006 during the addition of a leap second. The USNO master clocks control GPS timing. They are accurate to within one second every 20 million years (Satellites are so picky! Humans, on the other hand, just want to know if we’re too late for lunch) USAF photo by A1C Jason Ridder.  Detail of Compass/ BeiDou2 system diagram

Detail of Compass/ BeiDou2 system diagram Hotspot 6: Beluga A300 600ST

Hotspot 6: Beluga A300 600ST

1. Sweet Wheels

Maringa, Brazil

√ The latest self-steering Volvo truck innovates the way Brazilian farmers handle their crops. The Swedish manufacturing company is on a mission to revolutionize the Brazilian sugarcane industry by providing a smart and crop-friendly solution.

1. Sweet Wheels

Maringa, Brazil

√ The latest self-steering Volvo truck innovates the way Brazilian farmers handle their crops. The Swedish manufacturing company is on a mission to revolutionize the Brazilian sugarcane industry by providing a smart and crop-friendly solution.

The Usina Santa Terezinha Group provided Volvo with a test area to try out the company’s new self-driving truck. Located in Maringa, west from Sao Paolo, the sugarcane field produces sugar and ethanol for the Brazilian group. The Volvo truck was developed to investigate how automated driving could solve the problem of steering over crops. If successful, this could improve the condition of planted crops for quality harvest – up to 10 tons per hectare per year, which also means increased revenue.

The bespoke Volvo truck is equipped with a driver assistance system that automates steering. The technology is designed to ensure that the vehicle is always on the right course as it drives alongside the harvester. By doing so, the crops remain untouched and in good condition. Using GPS receivers, the truck follows a coordinated-based map as it drives through the sugarcane field. The front wheels and the entirety of the truck are driven with utmost precision by equipping the vehicle with two gyroscopes. This ensures that the truck doesn’t veer for more than 25 millimeters laterally from the programmed path. The technology promotes a more convenient way of harvesting sugarcane crops as drivers are being freed from the exhausting job of constant precision steering. It makes it easier for them to remain focused on the overall task in a more relaxed and safe method throughout the shift.

2. Floating Technology

China’s Fujian province

√ Titan Technologies Corporation has ordered two Fraunhofer IWES LiDAR measuring buoys for the surveying of the Zhangpu and Changle off-shore wind farms planned for off the coast of China’s Fujian province. This will be the first time a floating LiDAR (Light Detection and Ranging) system will be used for offshore wind measurements in China.

The buoys will be used to measure the wind conditions in the designated locations to allow precise calculation of the wind farm’s electricity yield. GPS can be used with this technology to give the position of these “floaters” directly.

The projected wind farms are owned by the China Three Gorges Corporation (CTG), which received the contract to build two wind farms with a total capacity of 2.8 GW. Titan Technologies has been engaged by CTG to perform the measurements. The company will also be completing the installation work, servicing, and data evaluation. Fraunhofer IWES researchers developed not only the design of the IWES LiDAR buoy but also the correction algorithm, which eliminates buoy movements from the measurements.

The Fraunhofer IWES LiDAR buoy has already been used multiple times for offshore measuring; most recently off the Scottish coast for the projected Firth of Forth wind farm. It measures wind speed up to 200 meters above the surface of the water. The buoy not only passed the Carbon Trust tests for floating LiDAR devices, but surpassed the requirements for accuracy and availability.

3. Robot Delivery for Mom

Sunnyvale, California

√ Residents in this California community were not surprised to get Mother’s Day gifts delivered to their homes last May, but some were caught off guard by the means of delivery —a small, white robot blasting classical music.

Starship Technologies, a London-based company that uses fleets of wheeled robots to make deliveries around the world, debuted in Sunnyvale on Mother’s Day. These robots, which resemble rolling coolers, are being used around the globe. Also in May, Starship announced its first UK robot grocery delivery.

Starship’s robots can deliver up to 20 pounds of goods over short distances and travel at a maximum speed of 4 mph. They use GPS technology to navigate sidewalks on the way to their destination.

Human operators monitor the robots remotely in case extra assistance is needed, and the company says they can handle round-trip deliveries of up to six miles. The robots run on rechargeable batteries.

4. Colliding Drones Underground

Sicily, Italy

√ European Space Agency (ESA) astronaut Luca Parmitano recently helped to explore the caverns under Sicily using a drone that deliberately bumped into its surroundings to build a map. ESA has been testing equipment, techniques and working methods for missions with astronauts in inner space for many years. Delving inside Earth and exploring caves often parallels the exploration of outer space, from a lack of sunlight to working in cramped spaces and relying on equipment for safety.

This CAVES-X1 expedition saw Luca join a scientific expedition organized by La Venta Association and the Commissione Grotte Eugenio Boegan in the La Cucchiara caves near Sciacca, Sicily.

Luca took geological samples and tried a new way of probing hard-to-reach spaces: a Flyability drone deliberately bumped into walls to learn how to navigate and to map tight areas that are too dangerous for humans.

ESA’s course coordinator, Francesco Sauro, an experienced caver and field geologist, remarks: “The drone used its thermal camera to map how the cave continued all the way to an unexplored area featuring water, impossible to reach for humans. These tests will help us understand which technologies can be used in future exploration of lava tubes on Mars, for example.” ESA’s strategy sees humans and robots working together to explore and build settlements on planetary bodies, as well as improving our understanding of our origins, and the origins of life in our Solar System.