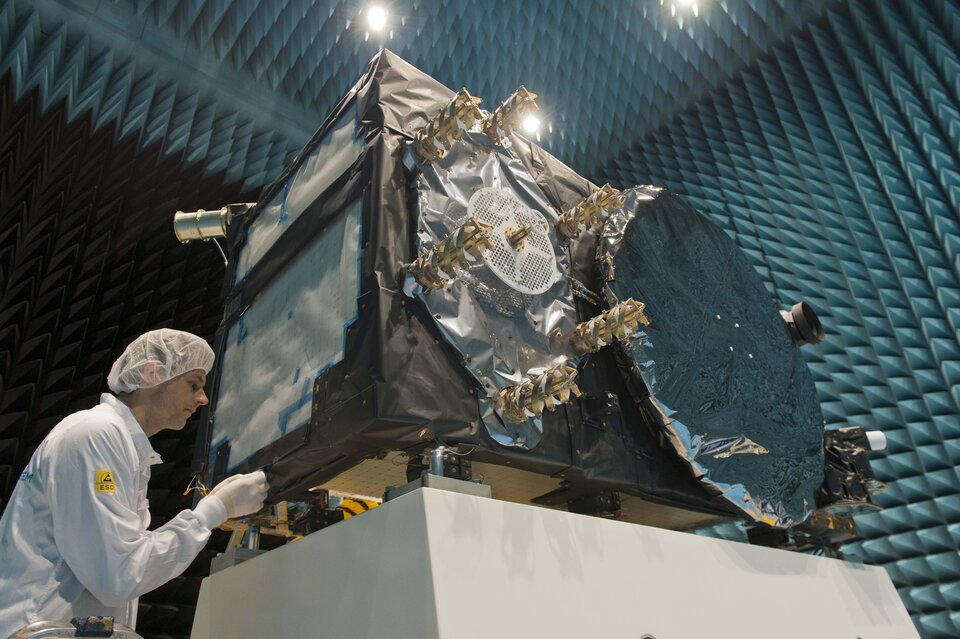

Testing of the first pair of Galileo Batch 3 satellites at the European Space Research and Technology Centre (ESTEC) was completed in April, and they are now in storage on site. Three more new Galileo satellites have since arrived from OHB in Germany to begin the rigorous pre-space checkout. A total of 12 Batch 3 satellites to bolster and advance the European GNSS will pass through Europe’s largest satellite test facility, located amid sand dunes along the Dutch coast, on their way to the launchpad in French Guiana. Two are scheduled to rise into orbit later this year.

The 3,000 sq. meter environmentally-controlled complex hosts test equipment to simulate all aspects of spaceflight. Newly-arrived satellites begin by undergoing a two-week immersion in vacuum and temperature extremes that mimic the conditions it faces in space. This thermal–vacuum test takes place inside a 4.5 m-diameter stainless steel vacuum chamber called Phenix. An inner box called the thermal tent has sides that are heated to simulate the Sun’s radiation or cooled down by liquid nitrogen to create the chill of Sunless space.

Another test involves switching on all satellite systems within the Maxwell Test Chamber, which is fitted with shielded walls blocking out all external electrical signals and spiky, radio-absorbing ‘anechoic’ material that line the chamber to prevent signal reflections. Kept isolated in this way as though floating in infinite space allows ‘electromagnetic compatibility’ testing. Each satellite is switched on to check all its systems can operate together without harmful interference. Then, once the satellites’ solar wings are fitted, which come from Airbus Netherlands in nearby Leiden, they can undergo ‘mass properties testing’. This involves measuring to check their centre of gravity and mass are aligned within design specifications. The more precisely these are known, the more efficiently each satellite’s orientation can be controlled with thruster firings in orbit, potentially elongating its working life by conserving propellant.

Each satellite also undergoes acoustic testing in the LEAF (Large European Acoustic Facility), effectively the largest sound system in Europe. A quartet of noise horns are embedded in one wall of this 11 m-wide, 9 m-deep and 16.4 m-high chamber, generating sound by passing nitrogen gas through the horns, surpassing 140 decibels in all. Accelerometers placed within the satellite checked for potentially hazardous internal vibration during this trial by sound.

The Test Centre is operated and managed by European Test Services for ESA. Once each satellite’s test campaign is over, they are shipped to Europe’s Spaceport in French Guiana and prepared for launch. The two tested spacecraft will leave to Kourou in October, to be launched at the end of the year.

Summer 2020 saw the start of construction of a new 350 sq. meter cleanroom for the ESTEC Test Centre. Most of the time the ESTEC Test Centre has several other test items as well as Galileo satellites within its walls simultaneously.