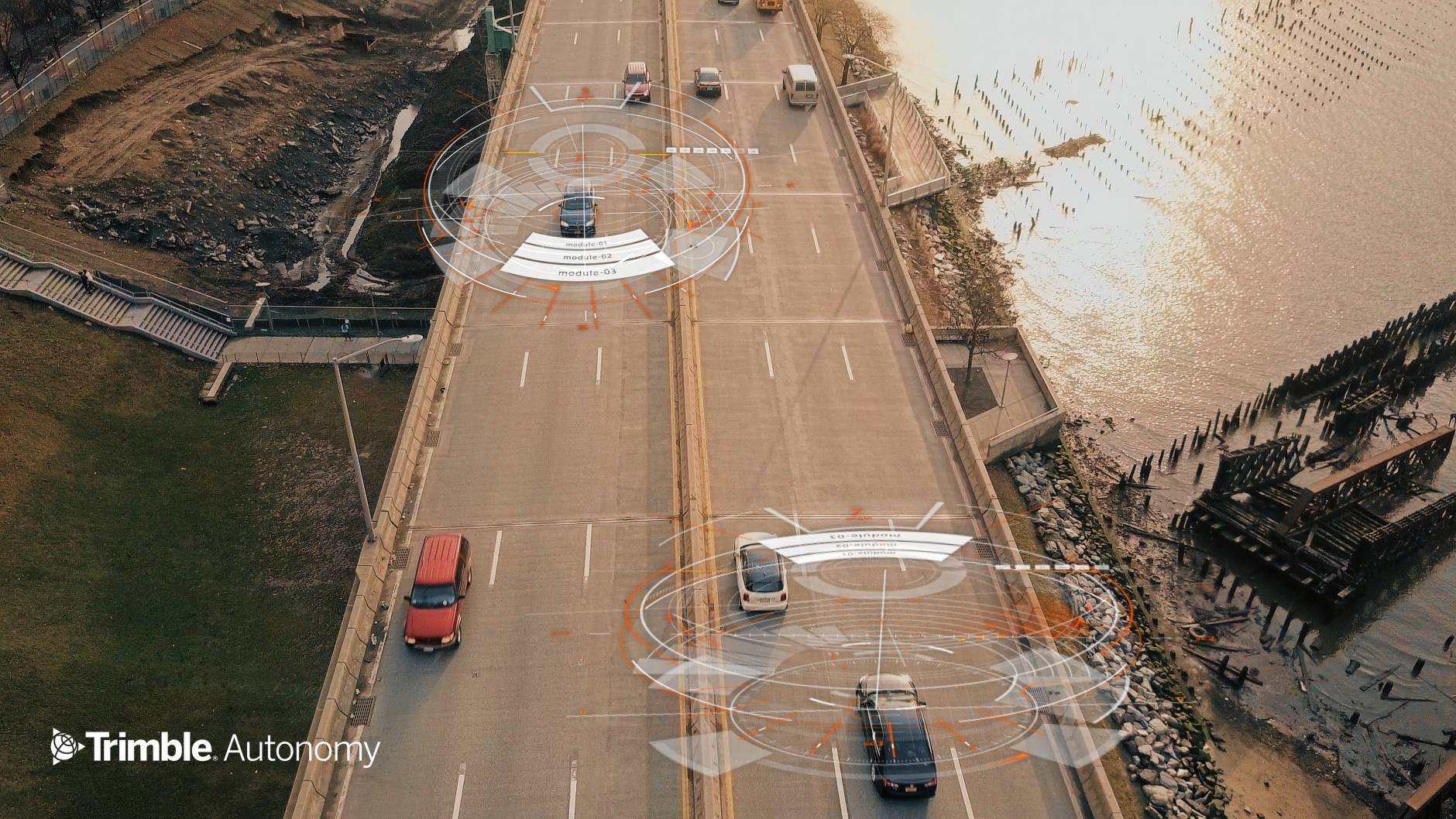

For passenger car companies developing advanced driver assistance and automated driving systems, absolute positioning is critical to the overall solution. However, providing cost-effective systems is key for high-volume applications from price-conscious automotive OEMs.

With nearly four decades of experience, Trimble Inc. has been a leader in precise positioning systems for passenger cars. The company has provided its RTX technology for GNSS/GPS correction to General Motors for the Super Cruise hands-free highway driving system since 2018 and more recently for the hands-off freeway driving capabilities of Nissan’s ProPILOT Assist 2.0 on the 2023 Ariya electric SUV.

At Informa’s AutoTech event in Novi, MI, last month, we caught up with Marcus McCarthy, Director, of Autonomous Navigation Solutions, for Trimble’s on-road division, to discuss the latest trends and challenges for passenger-car positioning.

The company’s GNSS chips are used extensively in agriculture and construction applications for which the value of positioning is higher and tied into a business process. That is not the case for the passenger car industry, which tends to use comparatively low-end GNSS receivers from other suppliers with one or two frequencies and a limited number of channels—all for cost reasons, according to McCarthy.

For passenger cars, the company avoids hardware but provides positioning-engine software that makes the best use of the data stream to and from GNSS receiver chips. Its solution improves the average precision from roughly 3-10 m to better than 20 cm in open skies, which makes a big difference in the targeted car applications, he said. “The challenge for us over the last number of years has been to make those inexpensive receivers as accurate as possible” with software.

The company’s positioning engine does this by outputting position, time, and orientation data, which are fused with data from precision maps and sensors like cameras or lidars. If data from those sources “line up, within reason,” then the system is deemed safe and can be used for driving, he said. If they’re not, that’s a risky situation, and so the system disengages.

“For a lane that is 3 m wide, a tolerance within that 20 cm is generally going to be good enough,” he said, for Trimble’s systems used in SAE Level 2 and 3 automated driving systems. However, he says that higher levels of autonomy may need greater precision—in the 10-cm range.

“We already have R&D systems that are there,” McCarthy said. “We will get there with this inexpensive [GNSS receiver] technology.”

However, he says that error estimation is even more important than precision at higher autonomy levels.

“When we output a position, we also output an estimate of error with that position,” he explained. “That estimate of error, in my mind, is more important than the precision of the position because it tells the system whether it can use the position data or not. It’s kind of a black-and-white thing when it comes to saving lives.”

At what point is the data not usable? He put it into numbers.

“The target integrity risk of 10-7, which is one failure in 1244 years of continuous operation,” said McCarthy. “When we get to Level 4, that’s the standard [at which] we’re operating. I’m not going to trust my family in a vehicle if it’s not operating at that level.”