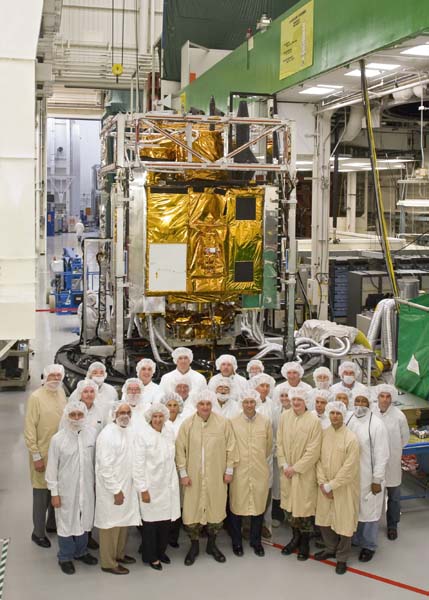

The Boeing Company will use its new “pulse line” process for assembling satellites to build GPS Block IIF satellites for the U.S. Air Force.

Constructed at the company’s facility in El Segundo, California, the new process is expected to shorten the time needed to build a space vehicle and will eventually be implemented on all Boeing satellite production lines.

For the Block IIFs the new process will reduce the travel distance of a space vehicle from 12,000 feet to 10,000 feet, according to John Duddy, director of GPS programs for Boeing.

The Boeing Company will use its new “pulse line” process for assembling satellites to build GPS Block IIF satellites for the U.S. Air Force.

Constructed at the company’s facility in El Segundo, California, the new process is expected to shorten the time needed to build a space vehicle and will eventually be implemented on all Boeing satellite production lines.

For the Block IIFs the new process will reduce the travel distance of a space vehicle from 12,000 feet to 10,000 feet, according to John Duddy, director of GPS programs for Boeing.

The new process will move parts through 13 pulse positions. New work cells, new tooling, standard work-planning packages and lean manufacturing processes will reduce the total build time per satellite and increase the number of vehicles moving through the line at one time, according to the company. The line is intended to eliminate rework, allowing parts to flow continuously and smoothly through the process.

“With 12 satellites on order, the GPS program is ideal for a manufacturing pulse line, because similar satellites can easily adapt to a process that mirrors mass production,” said Craig Cooning, vice president and general manager of Boeing Space and Intelligence Systems.

“The value of a pulse line is that it increases efficiency and therefore enables us to reduce costs," Cooning added. "As we continue to simplify our satellite designs in order to standardize the items that are inherent in every spacecraft built by Boeing, the implementation of a pulse line will yield tremendous benefits in the areas of efficiency and cost savings.”