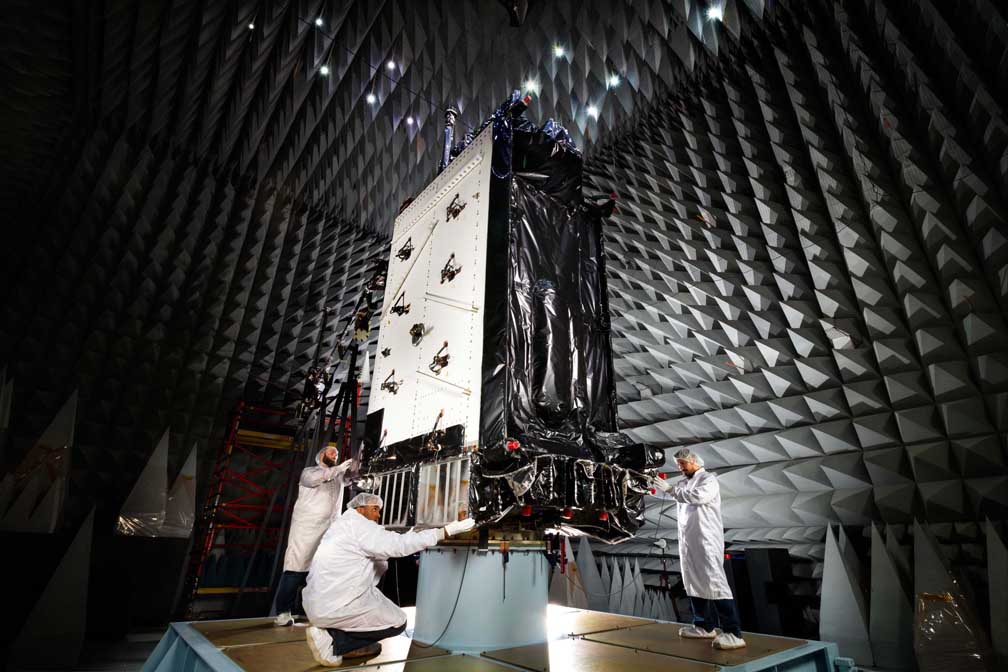

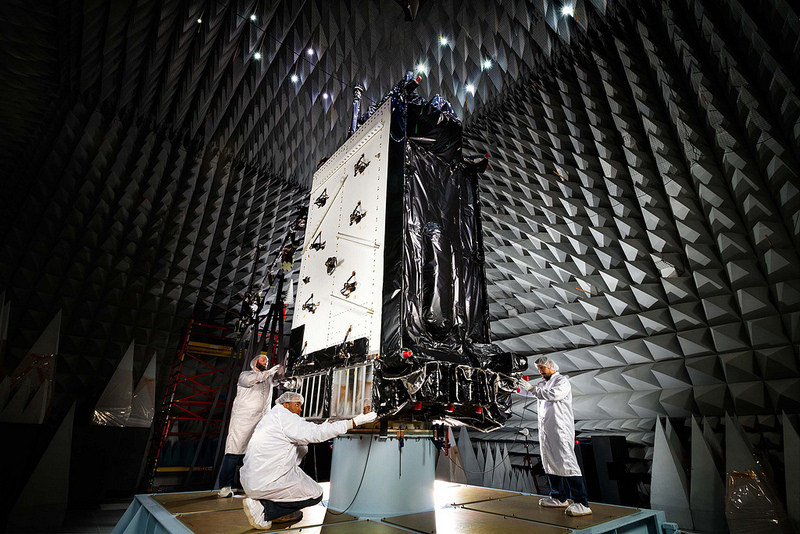

More than 300 engineers, technicians, and support personnel have been working on the GPS III program, including successfully completing space vehicle (SV) 01 testing, at Lockheed Martin’s processing facility near Denver.

The Air Force recently exercised contract options for Lockheed Martin to complete development of eight GPS III space vehicles (GPS III SVs 01 to 08). The eight vehicles are in various stages of assembly, integration and testing, according to the prime contractor for the next-generation spacecraft.

More than 300 engineers, technicians, and support personnel have been working on the GPS III program, including successfully completing space vehicle (SV) 01 testing, at Lockheed Martin’s processing facility near Denver.

The Air Force recently exercised contract options for Lockheed Martin to complete development of eight GPS III space vehicles (GPS III SVs 01 to 08). The eight vehicles are in various stages of assembly, integration and testing, according to the prime contractor for the next-generation spacecraft.

“We are in negotiations with the Air Force on options for SVs 09 and 10 and anticipate the award later this year,” Mark Stewart, Lockheed Martin vice-president of navigation systems, told Inside GNSS.

GPS III SV01 has gone through three rigorous environmental tests at Lockheed’s GPS III Processing Facility at its Waterton Canyonl, Colorado, campus to ensure the satellite’s operations in the stress of space, Stewart said. “Last fall, the space vehicle successfully completed acoustic testing, where it was subjected to high-level sound waves simulating the vibrations it will be required to endure during launch,” he said.

Thermal vacuum (TVAC) testing, is the most comprehensive and perceptive test performed at the space vehicle-level, according to Stewart. Last December, GPS III SV01 successfully completed TVAC testing. This testing ensures that all components and interfaces operate at space environment levels.

“TVAC testing not only proved the integrity of our first GPS III space vehicle, but also validated our overall space vehicle design, as well as our manufacturing procedures and facility functions [for follow-on production],” he said.

The satellite recently completed electromagnetic interference and compatibility (EMI/EMC) testing within the company’s anechoic test facility. The full space vehicle went through trials to ensure that the powerful component signals and payloads do not interfere with each other during operations, Stewart said.

Lockheed Martin said it would validate GPS III design over the next 26 months, as part of the Air Force’s GPS III Space Vehicles 11+ Production Readiness Feasibility Assessment. In May, the Air Force awarded Lockheed Martin a $5 million contract for Phase 1 of this procurement for future GPS III satellites. GPS III competitors Boeing Network and Space Systems and Northrop Grumman Aerospace Systems received feasibility assessment contracts at the same time.

The addition of a new laser reflector array (LRA) and a search-and-rescue (SAR) payload are acquisition requirements, starting with the 11th GPS III satellite. While the Air Force has not awarded contracts for these payloads yet, Lockheed Martin and the service demonstrated a Delta Preliminary Design Review (dPDR) addressing how the GPS III space vehicle design could incorporate LRA and SAR, Stewart said.

Lockheed Martin expects the SAR payload to come to the GPS III program as government-furnished equipment (GFE). Last year, the Canadian government was in talks with the U.S. Defense Department to install 24 search-and-rescue repeaters on GPS III satellites.